AI front Scope

AIfScope

About our Products

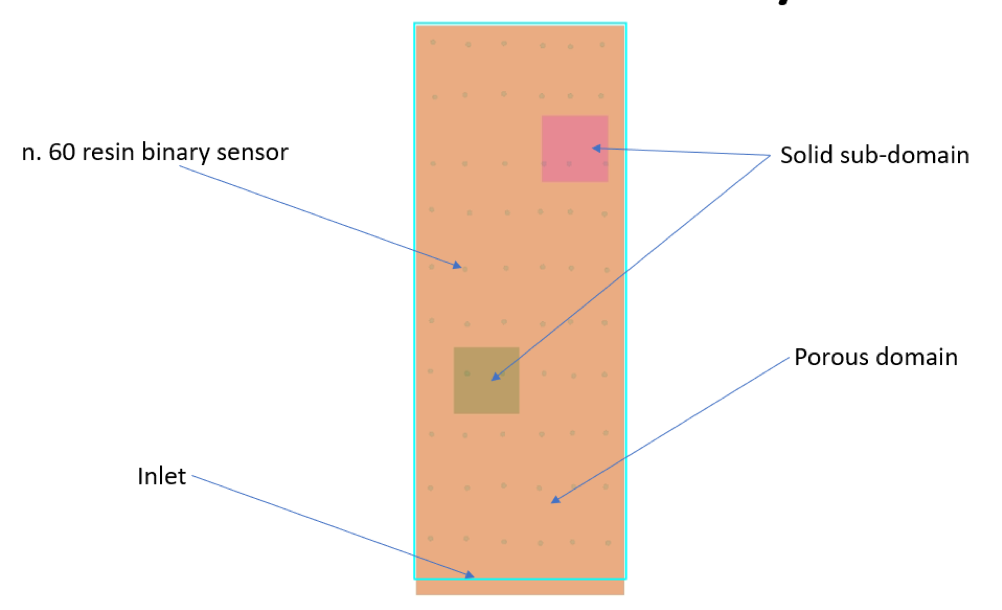

AIfScope (Artificial Intelligence front Scope) Vacuum Assisted Resin Transfer Molding (VARTM) real time monitoring

Vacuum Assisted Resin Transfer Molding (VARTM) is a closed mold, out of autoclave composite manufacturing process. Due to its low cost and low time-consuming, it is widely used for producing large 2D/3D components in the following sectors: aircraft, shipbuilding, automotive, wind energy, defense industries.

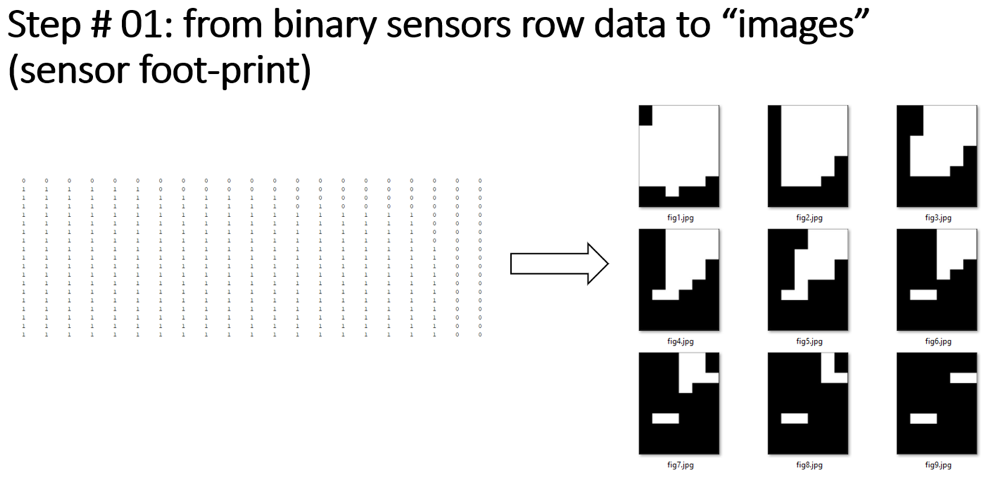

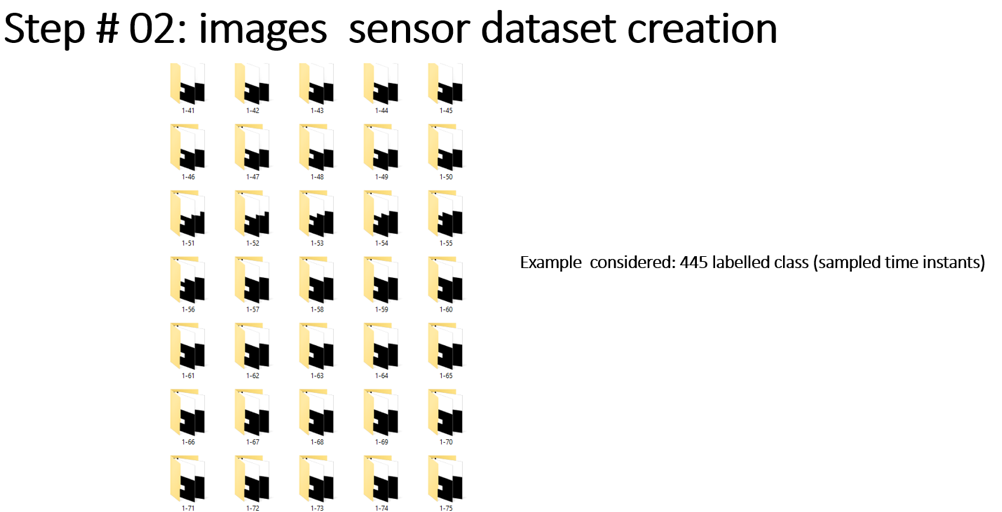

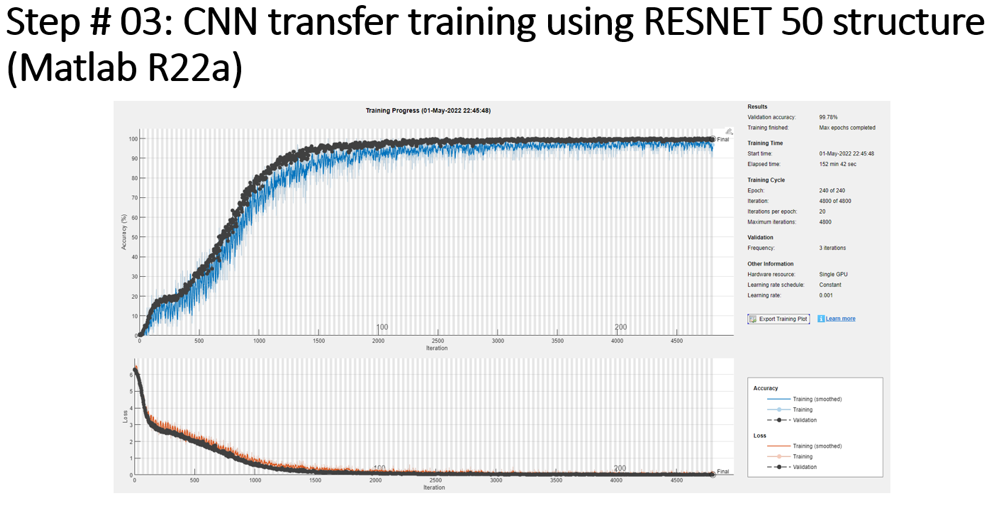

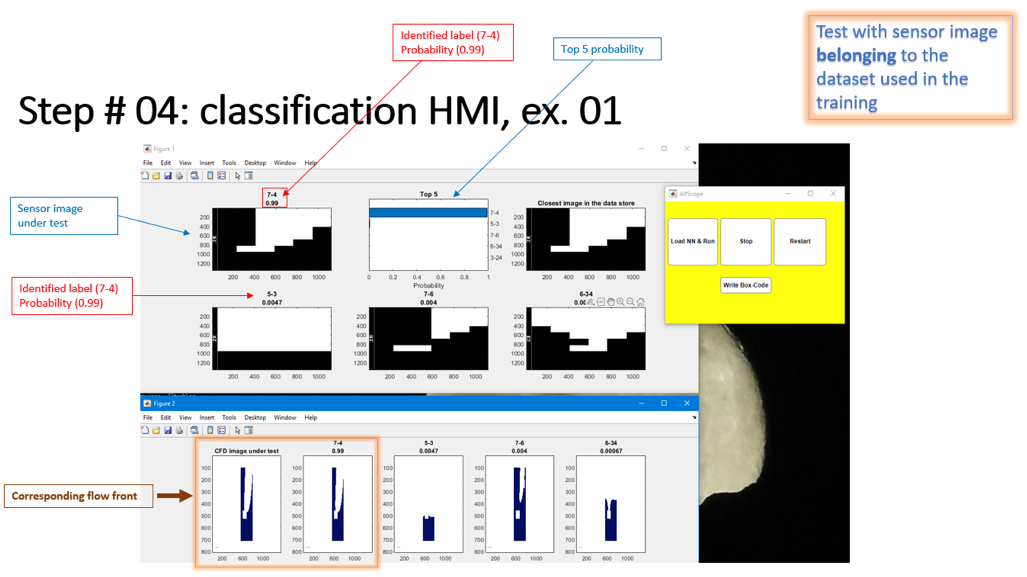

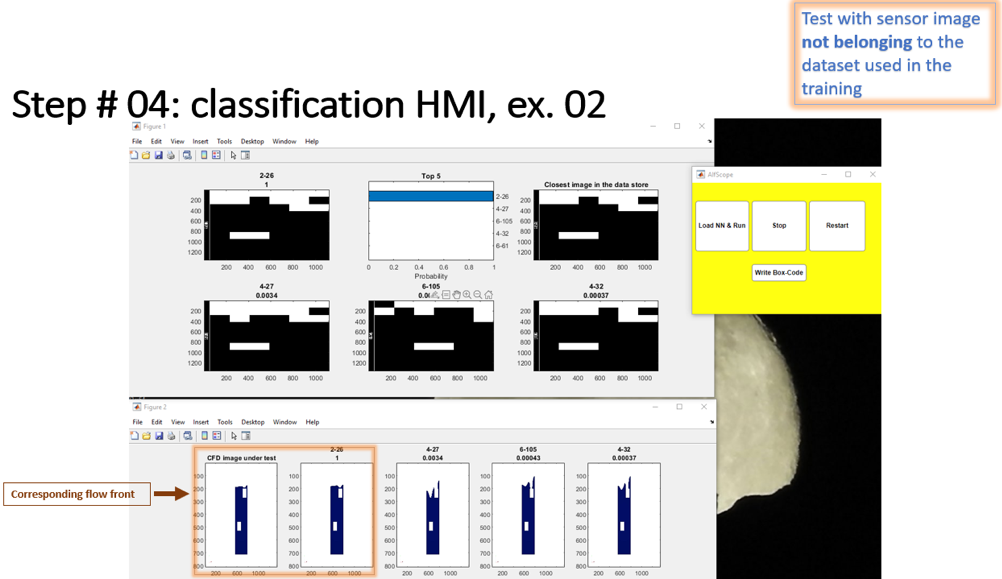

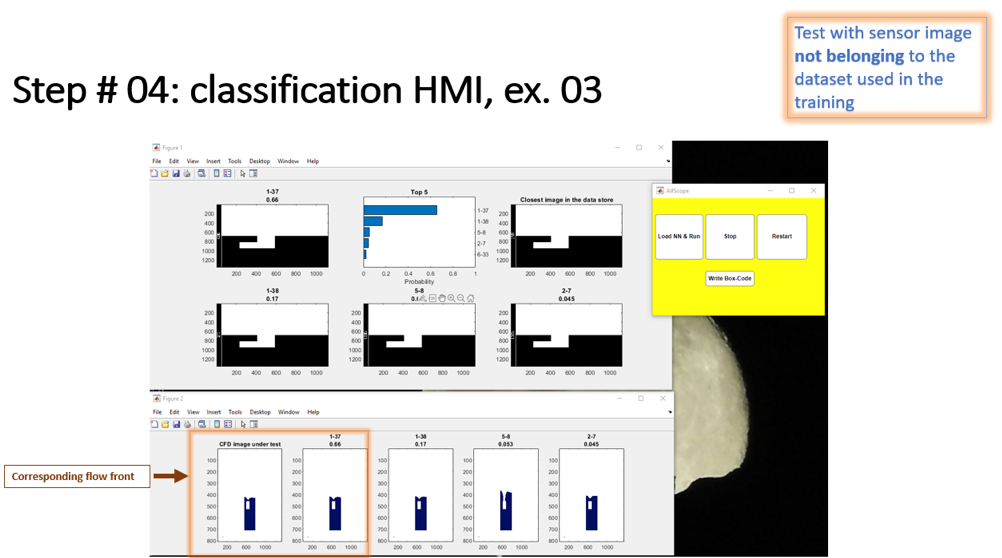

Practical VARTM monitoring is based on binary resin presence sensors. Our monitoring tool presented here, named AIfScope (Artificial Intelligence front Scope), transforms the binary sensors raw data into a foot-print synthetic image of the resin advancement front at a fixed or variable sampling rate. By CFD (Computational Fluid Dynamics) and multiple runs changing the input parameters (resin permeability distribution, inlet pressure, vacuum level), we obtain the set of configurations to cover all the real-world situations. Sampling the CFD numeric sensors we obtain the set of synthetic images. Such images are collected into a labeled dataset used to train a CNN (Convolutional Neural Network) to retrieve the most reasonable time-varying resin front. The HMI (Human Machine Interface) can be used by the operator to “see” inside the mold the advancement of the resin front. Moreover, this estimated resin front can become the input of the process feedback control strategy.

Implementation of surrogate model CNN-based to estimate the resin front based on the binary (0/1) resin sensors during filling process evolution, steps:

- transform the sensor output in image each sampling instant

- create the dataset of “sensor image”

- train the CNN

- perform the classification

- present the result to the operator (HMI) in a visual way, easy to be understood even to not-skilled personnel